Blueprint for Successful IIoT Implementation

Industry expectations in the context of Industry 4.0 are high. The promise of fast innovation, extreme productivity, simplified supply chain, greater visibility, improved decision-making, and greater profits are just some of the expectations from this technology. However rate of success in IIoT implementations is abysmal. According to a Cisco survey 76% of respondents considered their IOT initiatives failures, and a majority said that IOT initiatives looked good on paper, but turned out to be more complex than expected.

The success of Industry 4.0 initiatives depends a lot on ‘business first’ strategy and appropriate adoption of technology to serve business goals. IIoT implementation extends beyond the technology and the sensors and the automation and the machines that create this connected network. The hallmark of Industry 4.0 lies in the open and collaborative environment it creates – and along with the technologies in use, it is the people and the processes that make up this new manufacturing environment. So, what is the blueprint for success?

There are multiple stages in adoption

- Strategy

- Roadmap

- Planning and Budgeting

- Implementation(s)

- Post-Implementation

Strategy

The strategy has to revolve around business (products and services), people, assets and infrastructure. Evaluate your current business goals in all these areas and think about changes expected in future. Then build an IIoT strategy that will support your current and future needs.

You should also identify broad areas of application of IIoT. These include Digital Engineering, Smart Manufacturing, Digital Supply Chain, Smart Services, Digital Workplaces and more. Evaluate how applications in these areas will deliver value and fulfill your business goals.

For example,

- Digital Engineering can be employed to create Digital Twins, enable more collaboration in R&D, or be used for digital modeling and simulations.

- Smart manufacturing promises production improvements, prescriptive and predictive maintenance and consequent quality improvements.

- Digital supply chain provides E2E visibility, better supply-demand planning, and smart warehousing.

- Smart Services help in smart asset management and creation of new business models such as the pay per use business model.

- It also helps in providing multi-channel customer support.

- Creating a digital workplace includes accounting for mobility solutions, workplace security, and digital HR.

Roadmap

Building roadmap starts with creating cross-functional teams that will drive IIoT initiatives. They have to consider following aspects

- Deciding the approach towards adoption – local or global approach | top-down or bottoms-up approach

- Identifying the pain points these initiatives shall solve

- Deciding priorities

- Identifying applications and their phases

Whatever is your roadmap, please ensure that you start small, learn and then scale up!

Planning

Planning has to focus on – people, infrastructure and partners/solutions.

Engaging the Workforce

Identifying the Right Partner and Solution

There are a number of touchpoints that go into making a smart manufacturing solution. When evaluating the partner and the solution some points of consideration should be:

- Flexible connectivity options

- Solution features

- Ease of configurability

- Integration abilities

- Ability of architecture to scale

- Customization capabilities

- Ecosystem support

- Pricing and Licensing

Interested to read more?

Budgeting

Budgeting forms a critical part of the IIoT implementation plan. There are some indirect costs to be incurred and that needs to be budgeted properly. This includes infrastructure upgrades, security of connected assets etc. A key budget item is internal costs in terms of time commitment of various stakeholders.

For details, please read What goes into Costing of IIoT Project ?

Implementation

Once all above steps are successfully completed, you are ready to embark on the implementation phase. Taking up one or more roadmap items, organizations have to work collaboratively with their internal teams and the solutioning partner to get the best outcomes.

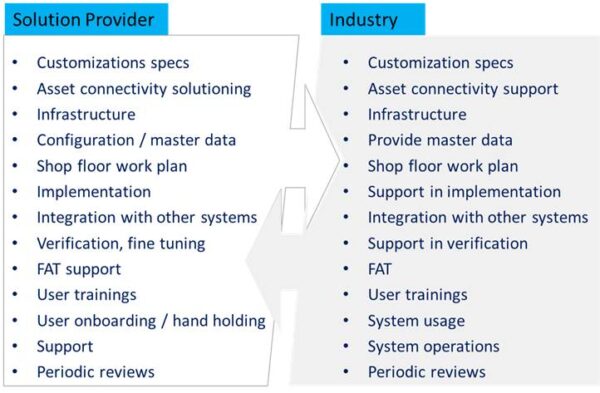

This infographic provides a list of tasks during implementation. As is obvious, it’s a collaborative project.

Successful implementation of IIoT solution is as much dependent on internal stake holders as it is on solution provider. For this it is critical that ‘Internal Owners or Champions’ are assigned to the project. Champions have to work with solution provider throughout implementation phase and beyond. They have to develop deep understanding of the solution, mobilize required internal resources from time to time for specific tasks, ensure timely support to end users as well as their training and hand holding.

There are several challenging items in above list. For example, designing most optimum connectivity solutions. Another one is verification of data / results. This seems straight forward, but the key is to ensure that all scenarios of shop floor working are captured and results verified in each case.

Thus with proper planning and ownership from internal champions and solution providers, IIoT implementation will go live successfully. However, the buck does not stop here. The post-implementation phase starts and it includes periodic review of solution, ROI calculations, enhancements etc. But that’s a subject for another article…

This article was originally published at http://blog.plantautomation-technology.com/blueprint-for-successful-iiot-implementation/